Responsible production

Below you can read a bit about our own production facilities, certifications, and the principles we have implemented in our production.

Safe production in proper production facilities

Our production facilities are certified through BSCI (Business Social Compliance Initiative), ensuring that our products are manufactured under proper conditions. This includes stringent requirements for building safety and working conditions (working hours, wages, etc.), which are reviewed and audited annually by the third-party auditor SGS.

All Leathers are tanned at LWG audited tannery

The Leather Working Group (LWG) is a global organization that sets stringent environmental and social standards for leather tanneries.

The requirements includes, for example:

– Water and energy consumption

– Wastewater management

– Air pollution and monitoring of vegetable tanning.

All our leathers are tanned on LWG audited tanneries.

Vegetable-tanned and dyed leather.

All our leather is vegetable-tanned. Here, we use no chemicals, but tan the leather using natural ingredients, among other things, tree bark and plant extracts.

Furthermore, the leather is naturally dyed.

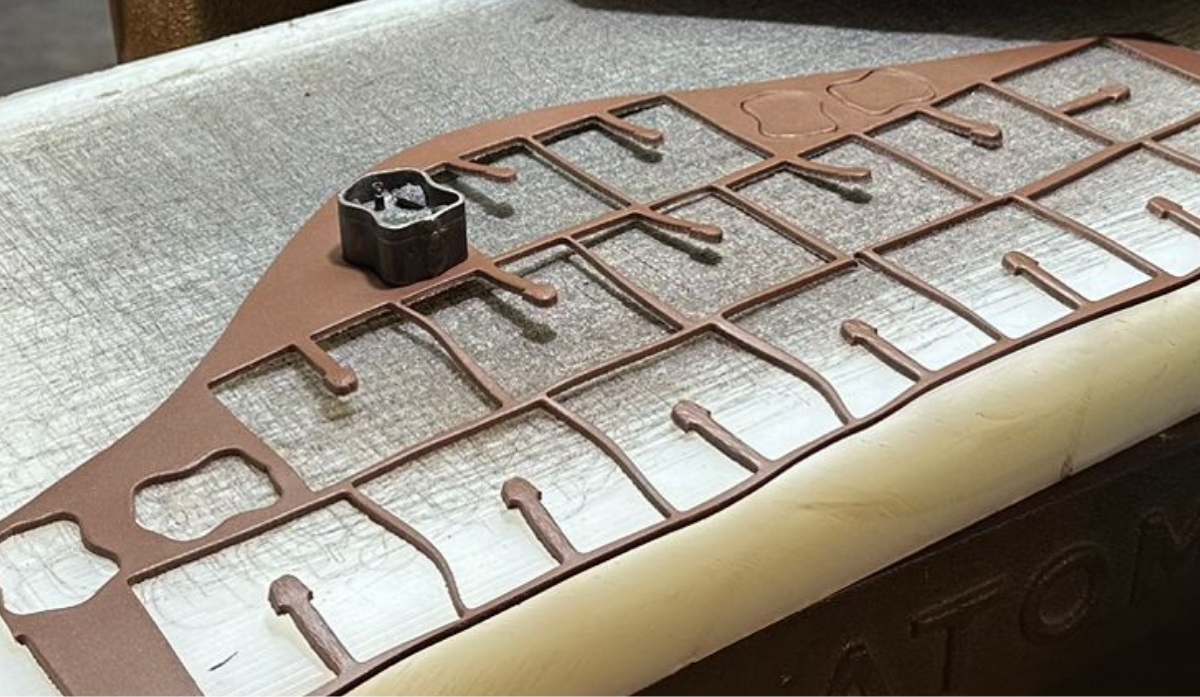

No waste of leather skins in production.

Production is planned so that all leather is utilized according to the Zero Waste principles.

After the smallest products, such as keyrings, are made, the remaining scrap is used for recycled leather (bonded leather), which is used in belts, sandal soles, and other products, ensuring that all leather is used up.